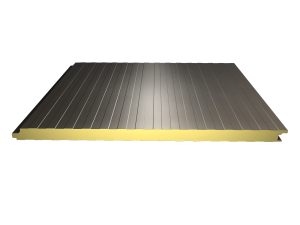

Sandwich panel is the system that protects the structures from external factors and offers the most practical and economical solution for a strong stance. Sandwich panels; It is used as modern, light and durable building elements, to cover the roofs and facades of buildings, to obtain insulated interior partitions or cold stores. Sandwich panels that protect you against external factors by taking place on all sides of your building and on the roof; It is produced by filling thick and low density insulation material between two thin high density metal surfaces. These structural elements, which have a high load carrying capacity despite their low weight, are produced ready for assembly. Which sandwich panel is suitable for your building? The selection is made by considering the heat, humidity, sound insulation and fire resistance needs of your building.

Technical Information

Metal sandwich panels are obtained by filling heat insulation material of various thickness and density between 2 metal sheets. Aluminum or galvanized sheet metal sheets are used in the construction of these metal sheets, the thickness of which varies between 0.5 - 0.7 mm.

It is possible to classify metal sandwich panels in 2 groups according to thermal insulation material and surface coating material.

Metal sandwich panels are obtained by filling heat insulation material of various thickness and density between 2 metal sheets. Aluminum or galvanized sheet metal sheets are used in the construction of these metal sheets, the thickness of which varies between 0.5 - 0.7 mm.

It is possible to classify metal sandwich panels in 2 groups according to thermal insulation material and surface coating material.

A. The Thermal Insulation Material

A.1. Metal Sandwich Panels With Mineral Wool Insulation

These are the panels that use mineral wool with a density ranging from 100 to 110 kg/m3 and a glass wool insulation layer with a density of 60-70 kg/m3 between the galvanized sheet or aluminum outer shell. Mineral wool filling is placed inside the panel with staggered inserts relative to each other. Since rockwool filled panels are heavier compared to other composite panels, the recommended maximum lengths for easy transportation and transportation on site are; 6 meters for 50mm thick panels, 80 mm. 5 meters for panels and 4 meters for 100 mm thick panels. The insulation materials used in the construction of the panels must be Class A non-combustible materials according to DIN 4102 (Fire Behavior of Building Metarials and Building Component - Part 2) and provide sound insulation in accordance with DIN 4109.A.2. Metal Sandwich Panels With Polyurethane Insulation

They are panels made by injecting polyurethane rigid foam material with a density of 38 - 42 kg/m3 between two shaped metal sheets. Polyurethane has a thermal conductivity coefficient of 0.035 W/mK. 4 cm of polyurethane foam; It has the same thermal permeability coefficient (U value) with 4.5 cm polystyrene foam, 4.5 cm mineral fiber insulation materials, 30 cm gas concrete, 50 cm brick wall and 240 cm reinforced concrete wall. For this reason, it is possible to use thinner panel thicknesses than other outer shell materials. They can be used in thicknesses ranging from 3.5 to 10 cm, taking into account the conditions of the region where they are applied.B. The Surface Coating Material

1366X768

1366X768